When managing a business or a team, it's often easy to get caught up trying to do the wrong things right. That is, focusing on things that don't contribute to achieving organisational goals. We might spend countless hours optimising processes and activities that don't contribute meaningful value.

How can we make sure we're doing the right things first? Answering this question can help lead us to achieving operational excellence.

What Is Operational Excellence?

You may have heard this phrase occasionally, yet it's one of those nebulous business terms that can mean different things to different people.

For our purposes, I define operational excellence as a business philosophy that focuses on developing a culture of continuous improvement that enables the company to be nimble and make smarter decisions. It's not just about achieving efficiency or maximising ROI. It's about ensuring the organisation’s long-term health by empowering employees and management to implement change.

Your organisation is most effective when you and your reports are contributing towards objectives that ultimately add value to customers, the company, and employees or are at least required by law/regulation. Anything else is likely a waste of precious time and resources.

Given the rapid pace of change we see worldwide, there has never been a more critical time for an organisation to work towards operational excellence. And for those seeking to become transformational leaders, developing operational excellence is an essential step in that direction.

How to Achieve Operational Excellence

It starts with having a clear strategic vision , mission, and measurable objectives. These pillars are the basis for any tactical workstreams you or your direct reports take to affect change.

The tactical plan should be SMART: specific, measurable, achievable, realistic and time-bound. All tactical actions should relate to your strategic vision and add value to the company, your customers, your employees, or any combination of these.

Suppose we assume the Strategic vision is to be a top-tier supplier in some industries. In that case, a tactical objective could, for example, be acquiring ten new clients for product X in a particular industry within the next quarter via cold outreach. To realise this tactical plan, we need operational tasks, such as developing a prospective client list, creating a plan to reach them via cold emails and/or other marketing tactics, and executing that plan continuously. If you have a good sense of your conversion rate, you could put numbers to each step, such as sending five cold emails weekly (or whatever it takes to get to 10 clients).

The critical element to this success (beyond excellent and cost-efficient execution) is knowing that you are adding value to the customer. So, product/service X should meet the customer's expectations. To do this, you can use the SIPOC framework. But it works better the other way around with COPIS

A COPIS (Customers, Outputs, Process, Inputs, Suppliers) map can help you define the necessary process to deliver towards customer expectations. Putting your customers' needs and requirements first ensures they are your focus.

| Supplier | Input | Process | Output | Customer |

|---|---|---|---|---|

|

|

|

|

|

Figure 1 Example SIPOC, Source Wikipedia

Starting with the customer, ask yourself what Outputs or results they need. What Processes deliver that output? What Inputs go into that process? And what Suppliers provide those inputs? Understanding the linkages helps identify what is truly creating value.

Of course, having the best, most customer-focused processes won't mean anything unless you have the in-house capacity and skills to manage the workload and deliver the expected outcomes.

Getting to Continuous Improvement

Continuous improvement is a good starting place for achieving organisational excellence, but it's essential to regularly assess company values, customer needs and performance against those benchmarks.

Which leads to the question: How do you know what's working?

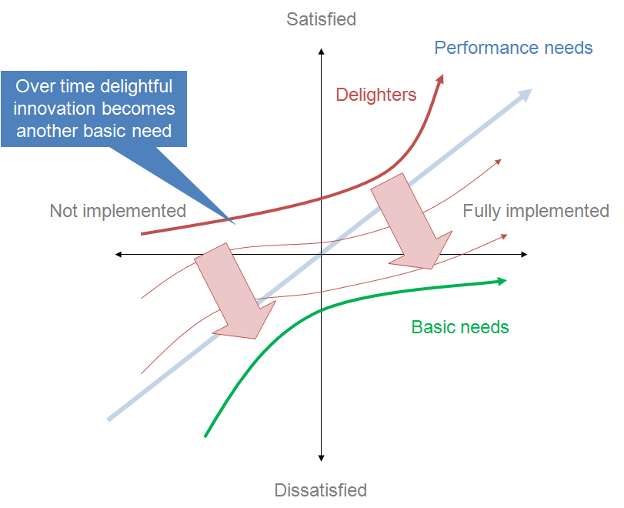

I often use the Kano model to identify when processes meet desired outcomes. Developed by a Japanese quality management professor, the Kano model plots customer satisfaction versus implementation level. It reveals the baseline for customer satisfaction versus what will delight them and lead to greater loyalty.

Figure 2 Kano Model, Source Wikipedia

Ultimately, operational excellence requires rigorous and routine examination of what your organisation is doing and why it is doing it. Are you doing the right things that directly contribute to strategic goals? And are you optimally performing them? And most importantly, does your team have this mindset? This mindful approach will eventually add excellent value for customers, employees, and all stakeholders.

Are you looking for ways to improve efficiency? We can help! Schedule a free clarity call and make a move toward developing operational excellence at your organisation.